Upgrade Your Sierra

What You Receive With Your Upgrade

Sierra Machinery has been manufacturing our World’s Fastest Skiving and Roller Burnishing Machine since the 1970s. With proper maintenance the hardware components of the Sierra skiver last virtually forever.

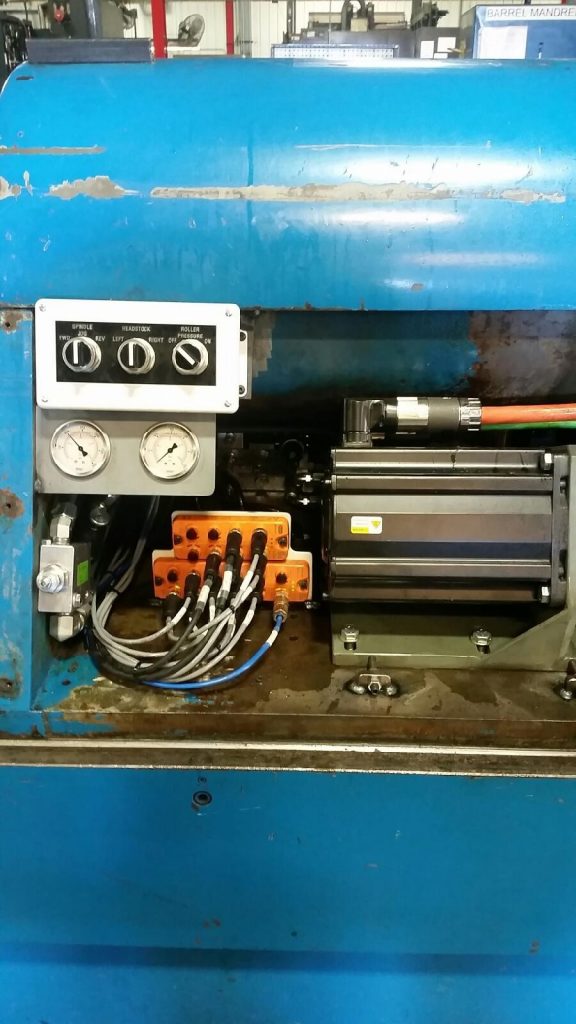

Not so for the electronic components, drives, and controls. Some of the motor drives, PLC components, and software have become obsolete and are difficult to support. Your machine may be so old it does not even have a PLC! The degradation of machine electronics may be causing increased cycle times, increased downtime, and reduced overall performance.

Upgrading your Sierra’s electronic controls with the latest equipment will renew your machine, improving its performance and making it easier to maintain. This upgrade will add years of life to your Sierra.

We find one of the most frequent drivers of machine downtime is the failure of obsolete components and attempts to replace them with non-factory approved parts. A Sierra Skiver controls upgrade is the most robust solution to keeping your Sierra running shift after shift.

The Features of the Sierra

Space Saving Footprint

PLC and Drives

New Servo Motor and Controls

Power Cabinet

New Digital Roller Pressure Controls